HEMPADUR 15500

HEMPADUR 15500 BASE 15509 CURING AGENT 97580

HEMPADUR 15500 is a two-component, amine adduct cured phenolic epoxy (novolac) paint, which cures to a coating with excellent resistance to a wide range of chemicals as tabulated in CARGO PROTECTION GUIDE.

LINK TO 15500 PRODUCT DATA SHEET

HEMPADUR 85671

85671 : BASE 85675 : CURING AGENT 97371HEMPADUR 85671 is a two-component, amine adduct cured phenolic epoxy (novolac) coating with very good adhesion and high temperature, water and chemical resistance.

LINK TO 85671 PRODUCT DATA SHEET

HEMPADUR BPA FREE 37301

37301: BASE 37308: CURING AGENT 98300 HEMPADUR BPA FREE 37301 is an amine-cured, solvent-free epoxy coating which cures to a strong and smooth lining. It is Bisphenol A epoxy resin free and comply fully with the Federal Food, Drug, and Cosmetic Act and call applicable food additive regulations, including 21 C.F.R. § 175.300 (“Resinous and polymeric coatings”).To be specified as a one coat system on internal surfaces of rail cars transporting liquid sugars, bulk quantities of dry food and/or plastic pellets for the manufacturing of food-contact materials.

LINK TO 37301 PRODUCT DATA SHEET

HEMPADUR FX4 37300

37300: BASE 37309: CURING AGENT 98300

HEMPADUR FX4 37300 is an amine-cured, solvent-free epoxy coating which cures to a strong and smooth lining. It comply fully with the Federal Food, Drug, and Cosmetic Act and all applicable food additive regulations, including 21 C.F.R. § 175.300 (“Resinous and polymeric coatings”).

As a one coat system on internal surfaces of rail cars transporting bulk quantities of dry food and plastic pellets for the manufacturing of food-contact materials.

LINK TO 37300 PRODUCT DATA SHEET

HEMPEL’S EPOXY 35480

BASE 35489 with CURING AGENT 95680

HEMPEL’S EPOXY 35480 is a two-component, modified, high-solids epoxy specially formulated as a lining in hopper cars. It forms a tough, abrasion-resistant coating with exceptional flexibility and chemical resistance.

LINK TO 35480 PRODUCT DATA SHEET

.

VERSILINE TL-91 S

VERSILINE TL-91 S: BASE 423V5 : CURING AGENT 927VC

VERSILINE TL-91 Sis a two-component, high performance flake-filled Novolac epoxy for steel and concrete tank lining applications. VERSILINE TL-91 S is well suited for coating structural steel in harsh fume or vapour service and offers excellent resistance to splash and spills of many corrosive chemicals.

Suited for linings and coating applications including chemical processing tanks, storage of mineral acids, caustics, fuel and a great variety of salts and their vapours.

LINK TO VERSILINE TL-91 S PRODUCT DATA SHEET

.

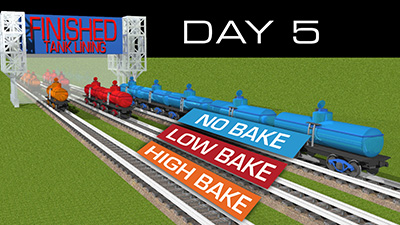

High Bake Technology provides most versatility but at a cost.

Check with your coating supplier to be sure your commodity is resistant and compatible with Low Bake or No Bake solutions..

Low Bake & No Bake Coatings Cargo Compatibility

Crude OilGasoline

Palm Oil

Methanol

Soybean Oil

Molasses

Styrene Monomer

Xylene

Ethylene Dichloride

Sunflower Oil

Benzene

Urea Ammonium Nitrate

Acetone

Ammonia Solutions, 28%

Butyl Ether

Caustic Soda, 50%

EDC

Fatty Acid

Heptanoic Acid

Methyl Ethyl Ketone

Potassium Hydroxide, 50%

Toluene

Trichloroethylene

VAM

“The most significant impact in reducing coating application costs and throughput times comes from tank car lining applications.”

From article in JCPL by Maria Betti from GATX.

CONTACTS:

Don Gill

Rail Key Accounts Manager(936) 523-5497

[email protected]

Jody Chisholm

Key Accounts Manager(312) 202-2443

[email protected]

HEMPEL USA Inc.

North Office & Plant

600 Conroe Park North Dr.

Conroe, TX 77303

Tel.: +1 936 523 6000

.

For complete information and specicifcations always refer to productg data sheets.

Check with your coating supplier to be sure your commodity is resistant and compatible with Low Bake or No Bake solutions.